Do you love chocolate? If so, then you’re probably wondering how it’s made. In this article, we will explain the process of how chocolate is made from bean to bar. It’s a long and fairly complicated process, but we’ve broken it down into 8 easy-to-understand steps. Stay with us as we explore the fascinating world of chocolate making!

The 8 Stages of Making Chocolate

1. Harvesting

Chocolate is made using cacao beans which come from the Theobroma cacao tree. This tree is grown by cacao farmers in tropical climates throughout the world.

Flowers can develop throughout the year, and the tree has the unusual trait of having both flowers and fruit on the tree at the same time. The fruit of the tree is known as the cacao pod.

Expertise is needed in deciding when the cacao pods are ripe and ready to harvest. Harvesting is usually done by hand as great care is needed to ensure the bark of the tree is not damaged. If damaged it can limit the number of flowers the tree produces in the future.

Once the pods are harvested they are cut open to remove the beans and pulp from inside. Each pod contains around 30 to 50 cacao beans.

2. Fermenting

The beans and pulp are exposed to oxygen and begin to ferment as soon as the pods are opened. This is an important process because it breaks down the coat of the beans, kills germs and bacteria, and is also crucial in developing the flavor of the beans.

Cacao farmers usually place the beans and pulp in special fermentation boxes for 5 to 8 days. The beans are turned and mixed every few days to ensure that they receive enough oxygen and that they ferment evenly. The temperature within cacao fermentation boxes rises to 40-50°C.

3. Drying

After the fermentation stage, the beans have a high level of moisture. This needs to be reduced to avoid over-fermenting. Most cacao farmers lay the beans in the sun to dry for several days. The beans are turned regularly to ensure they dry evenly.

In wetter climates, this is not possible so alternative methods are used. For example, in Papua New Guinea, beans are dried on open fires. This gives them a smoky flavor. Once dried, the beans are sorted and bagged before being shipped to makers around the world.

4. Roasting

The next stage of the chocolate-making process is when the bags of cacao beans arrive at the chocolate factory. Cacao beans are first sorted to remove any debris such as small rocks, twigs, or beans that became moldy during transit.

Once the beans are ready they are roasted in ovens. The exact temperature beans are roasted will depend on factors such as the type of bean or the average size.

Roasting cacao beans is crucial in developing their flavor. It also kills off any lurking bacteria whilst loosening the outer shell of the bean.

5. Winnowing

After the cacao beans have been roasted, the thin outer shell of the beans begins to separate from the cacao nibs inside. The shells are winnowed from the nibs using jets of air. The cacao nibs are used in the production of chocolate, whereas the shells can be used for other purposes, such as making cacao tea or even garden fertilizer.

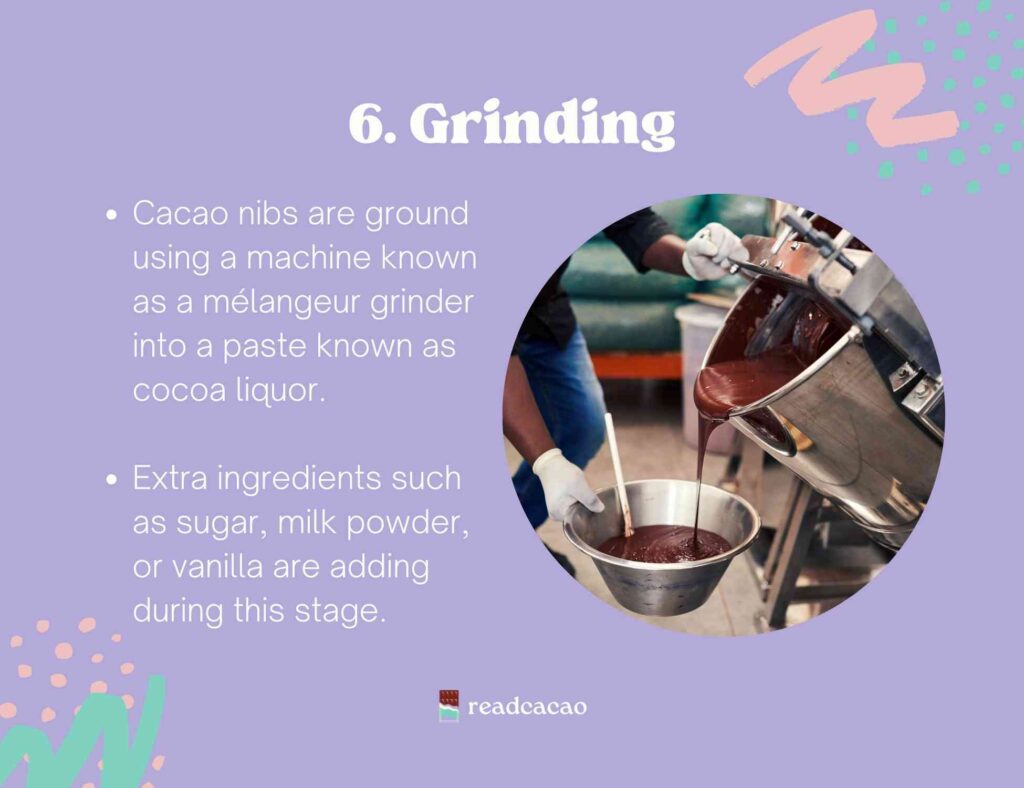

6. Grinding

Cacao nibs are ground using a machine known as a mélangeur grinder. This machine has two spinning stone slabs that grind the nibs. Nibs are made up of cocoa solids and cocoa butter. The nibs first turn into a thick paste also known as cocoa paste or cocoa liquor.

As the grinder continues to break down the nibs, the cocoa butter within the nibs begins to melt. The longer the chocolate is ground the smoother the liquor becomes. Some chocolate makers grind their chocolate for days to create extra smooth chocolate.

During the grinding stage, chocolate makers add extra ingredients such as sugar, milk powder, or vanilla. Extra cocoa butter is sometimes added to give the chocolate an extra creamy mouthfeel.

Once the chocolate maker is happy with the consistency of the chocolate, they pour the chocolate into large containers to cool and set. Some chocolate makers let their chocolate age for several weeks to develop a deeper flavor.

7. Tempering

Before the chocolate is turned into chocolate bars, it must first be tempered. Tempering chocolate is the process of raising and lowering the temperature of the chocolate to alter the crystals within.

Untempered chocolate is dull and crumbly. Tempered chocolate is shiny, firm, and has that recognizable snap. Tempering is traditionally done by hand but most chocolate makers today use a tempering machine.

8. Molding & Wrapping

Once the chocolate is tempered, it’s ready to be poured into molds to make bars of chocolate. The molds are shaken or tapped against a hard surface to remove air bubbles. They are then set aside to cool down.

As the chocolate cools down it also begins to solidify. One final quality check of the chocolate bars is done before they are wrapped in foil or paper packaging to keep them fresh.

The final chocolate bar is now ready to be shipped to a store near you!